RDI™ Cylinder

A single RDI™ cylinder is designed to remove all or most of the salt. Because of minimal pressure drop, multiple cylinders can be operated in series and at high flow rates, enabling processing of high total dissolved solids (TDS) streams without the need for intermediate storage. Each device removes a portion of ions from the stream until the target dissolved solids level is reached. This design aspect of the RDI™ Desalination System is critical to its superior performance and a key difference between RDI™ and other versions of capacitive deionization.

The processing capacity of a large-scale cylinder is up to 5 gpm depending on salinity of water.

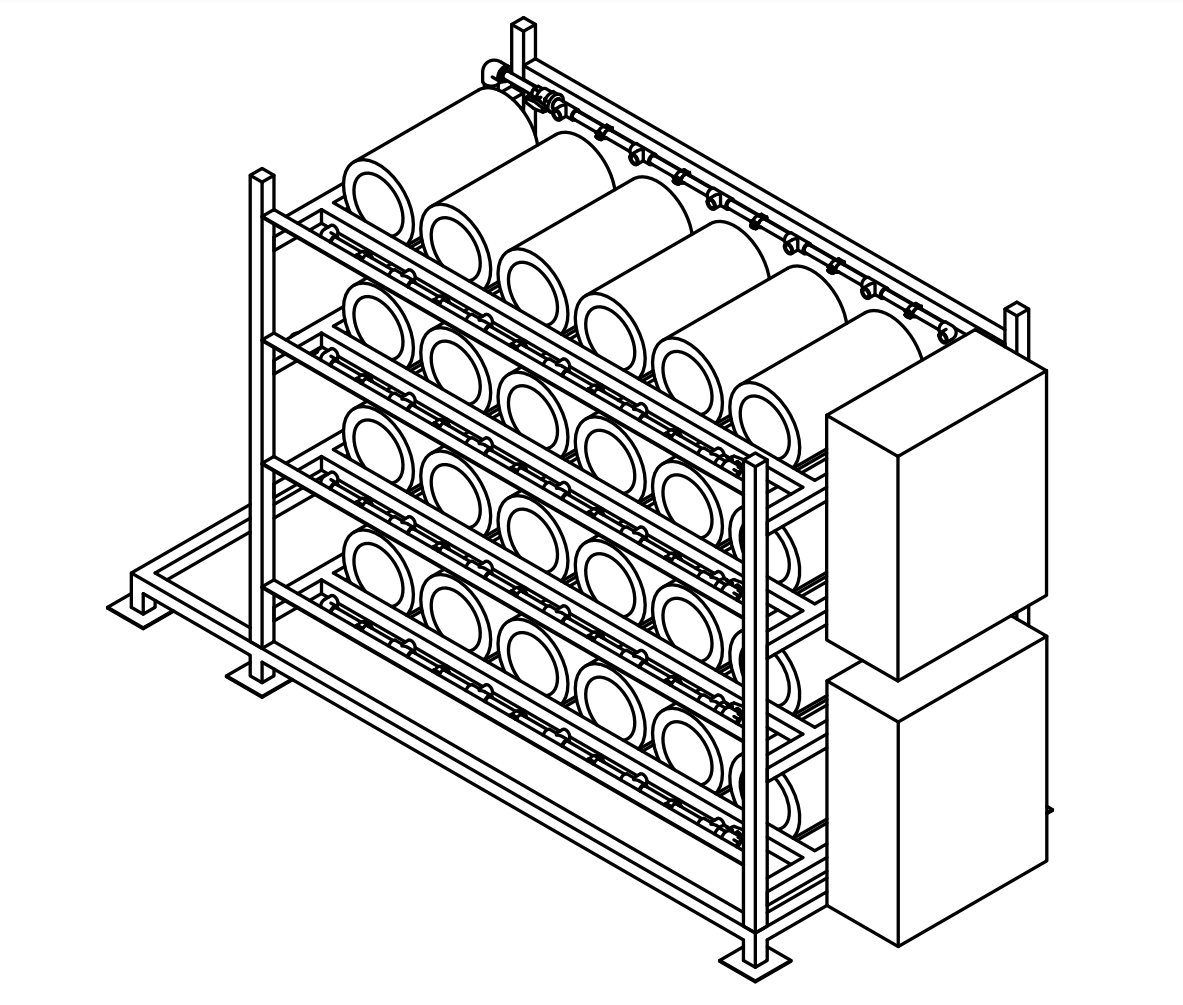

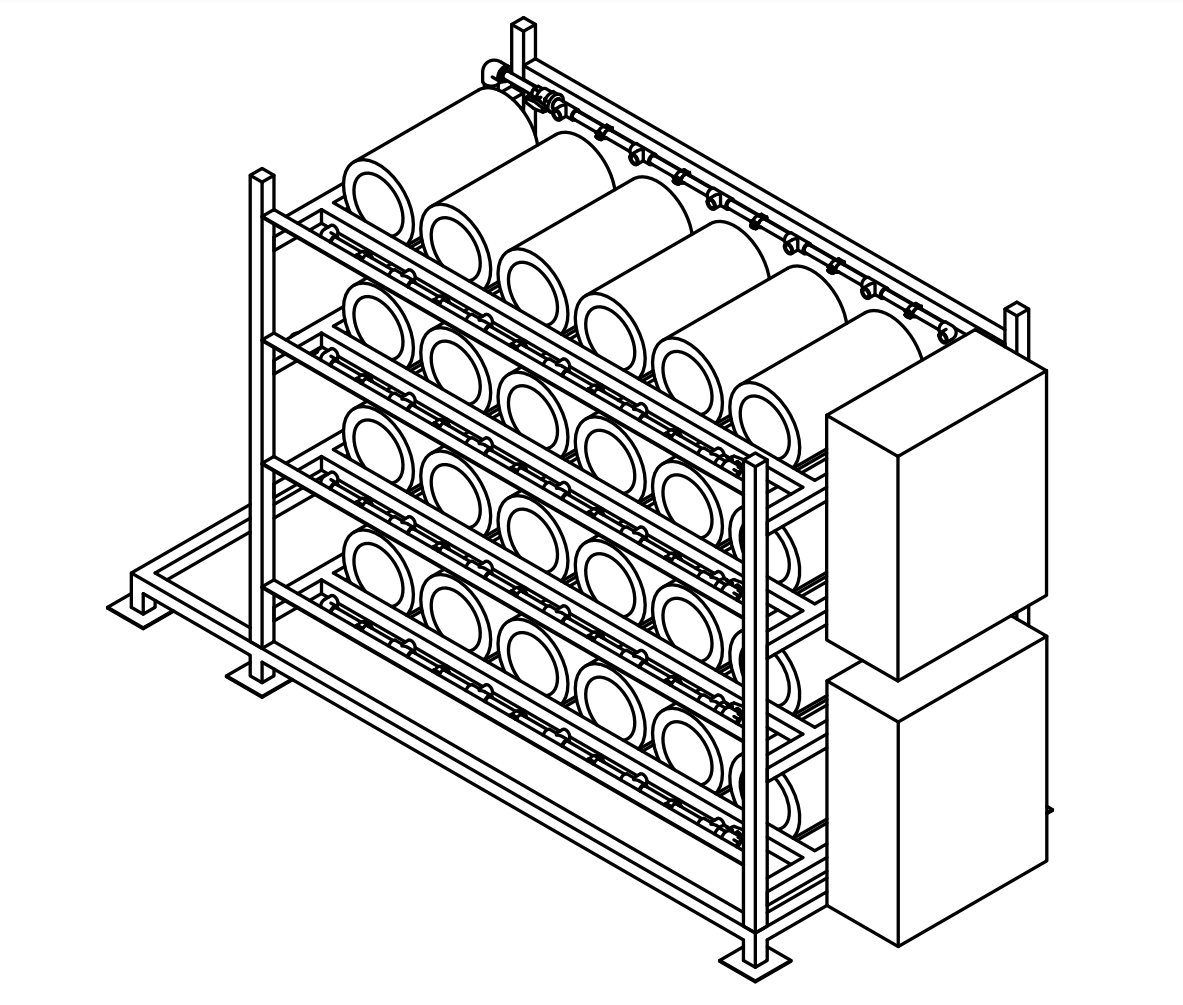

RDI™ System

A system consists of one or more RDI™ cylinders, associated valving, DC power supplies, and controls. A system will typically contain one or more modules depending on purification level and flow rate required. A typical system layout is shown above. The 4 ft by 14 ft skid contains 20 cylinders and is designed to fit in a semi or flatbed. A system can process up to 100 gpm depending on the incoming salinity level.

RDI™ Operation

The cycle time of the device ranges between 2 – 20 minutes for cleaning and 2 – 20 minutes for purging. Many applications require the use of more than one cylinder to allow constant flow to be maintained.

How can Atlantis’s RDI™ Desalination Systems save money and time?

RDI™ Options

The RDI™ design is very flexible and allows for a wide variety of configurations to best address each customer application. All designs are based on the use of the RDI™ supercapacitor, but the configuration and size of the system can be adjusted. For example, the number of cylinders, operating energy, and operating conditions can be adjusted. This includes the placement of 1 or more cylinders in series to reduce total dissolved solids (TDS) as needed by customer, placement of 1 or more trains of cylinders to increase capacity, and adjustment of operating voltage to meet energy requirements.